PhotonWeld MASTER-Pro Series: Designed for Heavy Industrial Fabrication

The Ecological Solution for the Heavy Welding Industry

Heavy industrial fabrication is characterized by its focus on assembling thick metal sections, typically exceeding 6mm in thickness, and constitutes a distinct segment within the broader metalworking industry. In contrast to conventional welding processes, heavy fabrication requires a meticulous application of welding techniques tailored to meet the specific challenges posed by large metal components.

The complexity of heavy fabrication arises from the significant size and weight of the metal parts involved, necessitating specialized welding methods to create strong and reliable connections. Furthermore, heavy fabrication projects often operate under stringent regulatory requirements and industry standards to uphold the safety and integrity of the final product, underscoring the importance of precision and adherence to established protocols.

Unlike standard welding tasks that may involve thinner materials and simpler joint configurations, heavy fabrication demands a higher level of skill and precision from welders.

PhotonWeld Master-Pro X100: "THE" new reference in laser welding!

Penetration 10 mm in steel

Width : 0~8mm

Dual wire welding: 2 x diam 2 mm

Anti-porosion function

Auto Calibrating function

Copper welding without problems

Weld from -30°C to + 60°C continious at 100% duty

With 1 day of obligatory training included

Consumes 28 % less than the other laser welding machines and till 85% less than standard welding machines

Now available for delivery.

Call for testing or info: +3256333240

sales@photonweld.com

www.photonweld.com

PhotonWeld Series

Real "ECOLOGICAL" welding

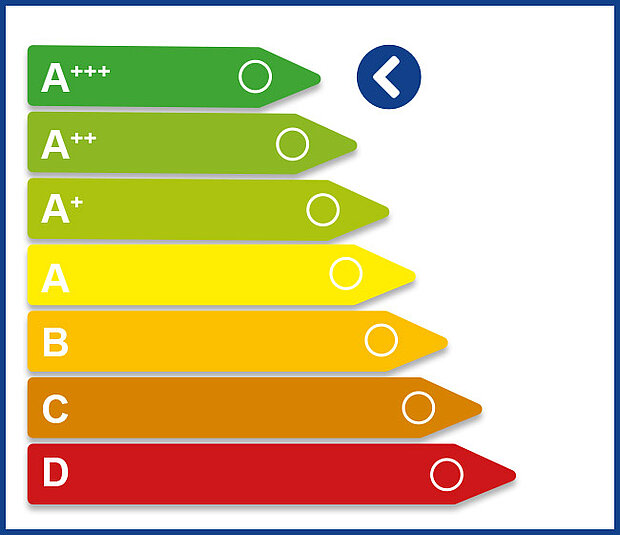

Class A+++

Minimal 20% less energy consumption compared to any other laser welding Machine

Standard laser sources are energy class A+ or Class A++

Most Ecological Laser Welding Machine on the market

20% Lower Energy consumption compared to the all the other.