LFT-III-3D Standard Range of cutting dimensions

Optional till diameter 350mm

3D Tube Laser Cutting finaly affordable

Why Use 3D Laser Cutting Machines?

Lasermach understands that reducing lead times on fabricated parts without sacrificing quality is a must for every manufacturer. with our high-quality and precise 3D tube laser cutting machines, you can tackle every project with a do-it-all, one-stop-shop approach that offers you many advantages.

Traditional tube laser cutting methods still deliver quality results, but they’re nowhere near as quick, efficient or precise as 3D laser cutting. As compared to sawing, coping, drilling and other fabrication processes, 3D laser cutting provides state-of-the-art technology that effortlessly delivers on your specifications.

Multi-axis 3D lasers have revolutionized tube fabrication by consolidating the functions of multiple traditional machines into a single, faster, more accurate, higher capability fabrication system. Our tube lasers can be fully automated, from loading and measuring stock to software that reads customer part drawings and programs the cuts to their exact specifications. They produce extremely precise, complex parts – incorporating bevels and weld prep – that are ready for welding and assembly upon delivery. And they are FAST!

LFT-3D Series Tube laser cutting Machines

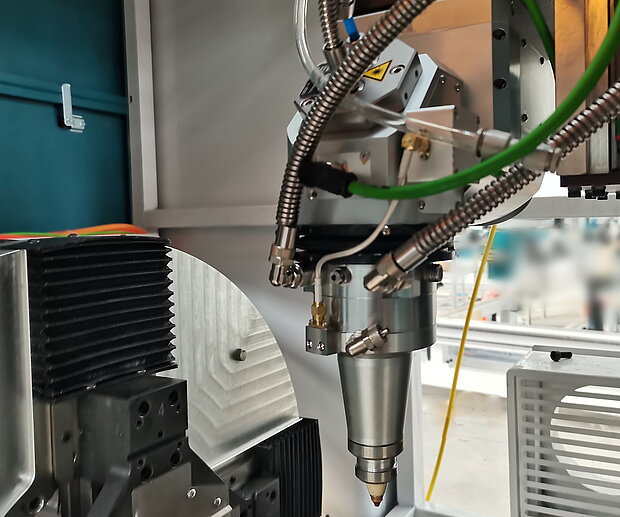

Fiber Laser 3D Tube Cutting Machines: Full 3D 5 Axis Tube Laser cutting

LFT-III-E-3D-Series

Small and smart Tube laser cutting Machine - 3D - 5axis

+- 135°

Ø220mm

max load: 160kg/m

ENTRY Version

Prototype

Small & Medium size Series

LFT-III3D-HD-Series

Heavy Duty 3D tube laser cutting machine

+- 135°

Ø220mm - optional Ø350mm

max load: 220kg/m - opt 300kg/m

Heavy Duty Version

Heavy Duty Tubes and Profiles

Small, medium and Big size Series

Optional full automatic tube Loading

LFT-III3D-HSP-Series

High speed & high precision 3D tube laser cutting machine

+- 135°

Ø220mm - optional Ø320mm

max load: 220kg/m - opt 300kg/m

High SPEED/ High Precision/Heavy Duty

Small-Medium and Big Series

Optional full automatic tube Loading

LTF-III-3D-Zero loss series

ZERO LOSS 5 axis Tubes and Profiles Laser cutting Machine

High-quality bevel cuts up to 135° on Front and Backside

Ø220mm - optional Ø320mm

max load: 220kg/m - opt 300kg/m

+ ZERO waste of material

Lasermach 3D 5axis laser Tube cutting

Affordable perfect tube cutting

Lasermach LFT 3th Generation Tube cutting

3D tube cutting is "the" new standard

| Model | ||||

|---|---|---|---|---|

| Lasermach LFT 3th Generation Tube cutting | LFTIII-3D-E Serie | LFTIII-3D-HD Serie | LFTIII-3D-HSP Serie | LFTIII-3D-ZERO Series |

| Entry - Economical Series | Heavy-Duty Series | High Speed& Precision Series | ZERO LOSS Tube cutting | |

| tube cross-sectional shape | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel |

| Basic parameter | ||||

| tube size range | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm |

| optional Φ350mm | optional Φ320mm | optional Φ320mm | ||

| Square tube □10 - □150mm | Square tube □10 - □150mm | Square tube □10 - □150mm | Square tube □10 - □150mm | |

| optional □240mm | optional □220mm | optional □220mm | ||

| One edge max length | 170mm | 180 / opt 280mm | 170 / opt 270mm | 170 / opt 270mm |

| Requirements for tubes minimum wall thickness | 0.3mm | 0.3mm | 0.3mm | |

| Maximum machinable tube length | 6200mm (opt 8200mm) | 6200mm (opt 8200mm) | 6500mm (opt 9200mm) | |

| maximum weight in chuck | 150kg | 190kg/ opt 450kg | 170kg/ opt 400kg | 170kg/ opt 400kg |

| Maximum tube weight | max 160Kg/m | max 220Kg/m -300kg(Φ350mm) | max 220Kg/m -300kg(Φ320mm) | max 220Kg/m -300kg(Φ320mm) |

| Maximum blanking length | 3000mm | 3000mm | 3000mm | |

| Shortest remaining material | 40mm | 40mm | 40mm | 40mm |

| Dimensions LxBxH | 9500mm x 2280mm x 2450mm | 9700mm x 2280mm x 2560mm | 10500mm×3120mm×2350mm | 10800mm×3420mm×2350mm |

| Machine weight | 6450 kg | 7600kg- 14800kg with ATC | 8600kg - 13400 with ATC | 9600kg - 14600 with ATC |

| Positioning accuracy | 0,02mm | 0.03mm | 0.025mm | 0.03mm |

| Repositioning accuracy | 0,01mm | 0.02mm | 0.016mm | 0.02mm |

| Max. Chuck rotating speed | 170r/min | 80r/min | ||

| Operation parameter | ||||

| axis maximum speed | 120m/min | 100m/min | ||

| X maximum acceleration | 1.5G | 1.5G | 1.5G | 1.5g |

| Y maximum acceleration | 1G | 1G | 1G | 1G |

| Φ20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| Processing precision | ||||

| □20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| □20mm square position size difference | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| Laser source | Raycus/MAX/IPG | Raycus/MAX/IPG | Raycus/MAX/IPG | Raycus/MAX/IPG |

| laser head | Han's Raytools/opt Precitec, WSX,.. | Han's, Raytools/opt Precitec, WSX,.. | Han's , Raytools/opt Precitec, WSX,.. | Han's , Raytools/opt |

| Automatic focusing function of laser head | incl | incl | incl | incl |

| Optical system | ||||

| Multi-stage perforation Technology | incl | incl | incl | incl |

| smooth cutting technology | incl | incl | incl | incl |

| Anti-slag protection function of double cyclones | incl | incl | incl | incl |

What are the advantages of bevel tube laser cutting machine?

-

One-time full finished job, improve efficiency

Bevel tube laser cutting machine can complete v, x, y and other bevels at one time. The bevel processing that need to be completed by traditional cutting, milling and other multiple processes can now be completed at one time, greatly improving efficiency, ensuring quality, and saving resources.

-

Zero clearance welding,reduces cost

Bevel tube laser cutting Machin can realize zero-clearance welding. In the subsequent splicing process, there is no need to process again, which reduces the process and greatly reduces the cost of manpower and material resources.

-

±60° flexible cutting

Bevel tube laser cutter has a 135° angle of swing cutting head, with a full efficient angle of cutting till 60° which has superior performance and can realize bevel cutting of the workpiece in the range of +60° /0°/ -60°. The cutting head is dedicated for 3D cutting and has an automatic focusing function. During bevel cutting, it can automatically adjust the focus position according to the thickness and angle of the cutting material to meet the cutting process requirements.

BEST TUBE Cutting Controller