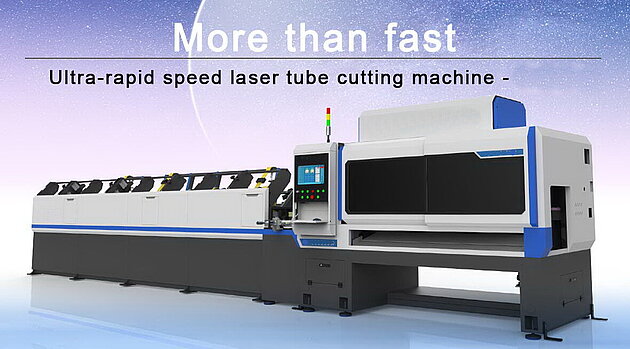

Fiber Laser Tube SAWING Machine

Tube diameter 24mm - Wall thickness 2,4 mm - Tube lenght 328mm - Soft Steel - TAKT Time = 1.78 sec - including last part push out and first part cut-off - 2000 pieces/hour

This tube cutting machine is faster than any high speed sawing machine!

FIBERSAW provide the cheapest, fastest and most flexibel tube and pipe cutting in the world!

All Fibersaw Machines have optional an interior clean wall function

No melted metal residu on the tube internal walls!

Fibersaw: super fast tube cutting machine : burr-free cutting of stainless steel tube

stainless steel tube diam 36 mm wall thickness 1, 6 mm cutting lenght 645 mm : with auto loading TAKT time : 3,48 sec super fast tube cutting

LOWEST Maintenance and cutting cost in the market!!

NO SAWBLADES !

NO SAWBLADES TO REGRIND!

NO STOPPING TO CHANGE SAWBLADE

NEVER TO CHANGE SAWBLADES FOR OTHER MATERIAL OR OTHER DIMENSIONS

ONLY ONE SETUP FOR ALL MATERILAS AND ALL DIAMETERS

Lifetime of laser SOURCE > 100.000 HOURS

> More than 20 years in cutting without problems!

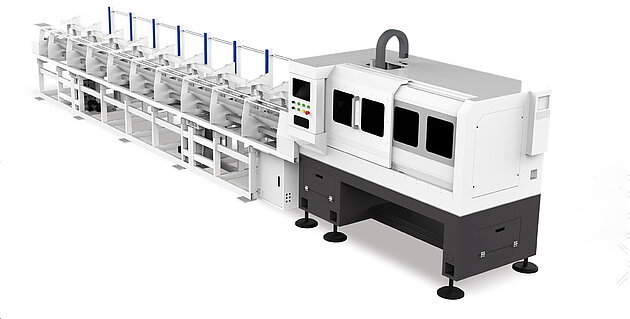

FIBERSAW®-FS42 Series

Fiber laser cutting system for round tube and pipes processing up to 42 mm in diameter.

Fibersaw®-Series are the compact machines in the Lasertube family designed for continuous production of smaller diameter and thinner wall tubes.

Simple to use and manage, extremely robust, designed for high production and frequent product changes.

Equipped with a 0.5 to 2 kW fiber source, FIBERSAW® FS42 is the right machine for thin wall and small diameter pipes and tubes.

SHORTEST TAKT TIME : 0,6 Sec/piece

FIBERSAW®-FS120-Series

Fiber laser cutting system for round tube and pipes processing up to 120 mm in diameter.

Fibersaw®-Series are the compact machines in the Lasertube family designed for continuous production of smaller diameter and thinner wall tubes.

Simple to use and manage, extremely robust, designed for high production and frequent product changes.

Equipped with a 1 to 3 kW fiber source, FIBERSAW® is the right machine for thin wall and small diameter pipes and tubes.

SHORTEST TAKT TIME : 0,8 Sec/piece

Cutting Samples :

Tube steel - wall 0,3 mm - Lenght 500 mm

: TAKT Time = 0,98 sec

Tube steel Ø 32 mm - wall 0,4 mm - Lenght 285 mm

: TAKT Time = 1,68 sec

FIBERSAW®-FS82-ULTRA Series

Fiber laser cutting system for round, square, rectangular, oval, .. tubes and pipes processing up to 82 mm in diameter and 60mm square.

Fibersaw®-Series are the compact machines in the Lasertube family designed for continuous production of smaller diameter and thinner wall tubes.

Simple to use and manage, extremely robust, designed for high production and frequent product changes.

Equipped with a 0.5 to 2 kW fiber source, FIBERSAW® FS82-ULTRA is the right machine for complex cutting of thin wall and small dimension pipes and tubes of any form.

SHORTEST TAKT TIME : 0,8 Sec/piece

More info on Fibersaw F60

Let us show you a unique way to cut pipe and tube method that is faster and cleaner than what you’re using now.

There are many ways to cut pipe and tube: band saws, cold saws, chop saws, shear,.. to name a few. But none can match our FIBERSAW

Superior performance in thin wall materials

The faster cutting speed of nitrogen assist fiber laser cutting on thin materials more than doubles machine productivity compared to any other cutting: thinner wall mild steel, stainless steel and galvanized are the materials that benefit the most from fiber laser cutting.

Zero laser maintenance required

The fiber laser does not require routine adjustments, component replacement or rebuilds. It does not consume laser gas. No need of saw blades or cutting discs. Laser beam quality is stable and consistent over time. It is ready to cut as soon as you turn it on. No warm up is required.

New materials for new opportunities

Copper and brass can be easily cut with fiber laser. Even tricky grades of aluminium and galvanized steel pipes are easily processed.

Far more efficient with much lower power consumption

The increased electrical efficiency of fiber laser technology drastically slashes the electrical consumption of the system, yielding savings on the utility bills and on the initial installation due to reduced requirements.

Minimum size, maximum production rate

FIBERSAW is small.

Occupying less floor space means having a smaller impact on the organisation of your production.

The ability to optimise the entire production flow and eliminate unneeded handling of bars and the parts frees up floor space and saves labor.

High speed processing and quality

Moving light, flexible tubes fast, without ever losing control and without the risk of jamming the loader: this is the result of our tube processing experience.

Our laser machines bring you a cost-effective, low-maintenance, environmental-friendly solution to your organization.

We deliver Fiber Laser Cutting machines that provides quality cutting and tight tolerances, low productivity loss between jobs and less maintenance costs.

Cutting solutions with high productivity

Tube Cutting Machine: CNC fiber laser SAW for tubes and pipes

The only high speed Fiber Laser SAWING machine on the market.

AFFORDABLE

Reduce your costs: Cut with light, NO SAWBLADES!

FAST R.O.I.

FIBERSAW FS-Series with Computer Vision system

High Speed Cut-to-Length Tube Cutting System - CNC Tube Cutoff Machine - CNC Tube Cutting Machine with Automatic Feed - Fully automatic metal pipe and tube cutting machine with auto loading - CNC Tube Cutting Machines - CNC Straight Tube Cut-off Machine - A Tube Processing System Designed for Automatic Feed & Cut - high Speed Tube Cut-Off Machine - High Speed Cut-to-Length Tube Cutting System - High Speed Cut-to-Length Tube laser Cutting System - CNC laser Tube Cutoff Machine - CNC laser Tube Cutting Machine with Automatic Feed - Fully automatic metal pipe and tube laser cutting machine with auto loading - CNC laser Tube Cutting Machines - CNC laser Straight Tube Cut-off Machine - A laser Tube Processing System Designed for Automatic Feed & Cut -- high Speed laser Tube Cut-Off Machine - High Speed laser Cut-to-Length Tube Cutting System