LASER WELDING MACHINES - LASER CLEANING MACHINES - LASER SAFETY MATERIALS

LASERMACH: Simply "THE" Best

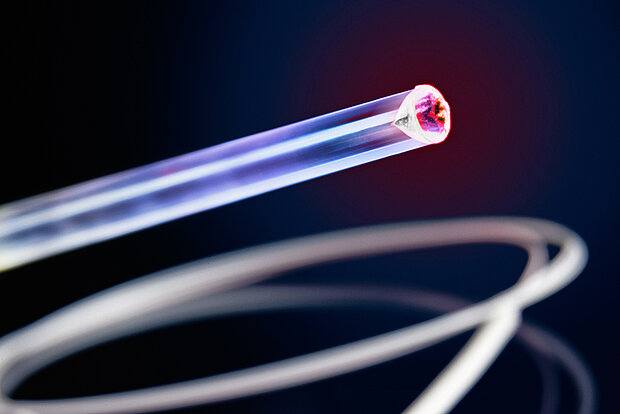

LASER WELDING

PhotonWeld PRO-Series : Compressor Cooled - Heatpump driven - Rain resistant - functional under 100% duty load - 30°C till +60°C

LASER CLEANING

PhotonClean - NO Surface Damage Laser Cleaning Machines with optional engraving and marking function

LASER PROTECTION

PhotonSafe © - Laser Protection equipment - Laser Safety equipment - Laser security equipment

Premium Laser Safety Equipment for laser Welding and Laser Cleaning

Laser Welding Safety and laser cleaning Safety

Premium Handheld Laser Welding Machines

Handwelding - Automatic Welding - Robot Welding - Cobot Welding

Lasermach PhotonWeld-A-Pro Series - Real Portable Handheld Fiber Laser Welding with air-cooling

PhotonWeld: The killer of electric welding and argon arc welding

Efficient, Fast, economical and ecological responsable handheld laser welding

Replacing the previously convnetional MIG, TIG and MAG welding systems with an Air-cooled PhotonWeld-A1600+ series fiber laser welding unit not only made welding much faster and economical but also makes laser welding possible in in- and outdoor operations, which indicates that the traditional welding of electric welding, argon arc welding, etc. will be replaced by laser welding.

PhotonWeld-APro Serie : perfect handheld fiber laser welding machine

Pure Portable Welding Power from -20°C till +60°C

With High Energy saving EcolEner® Technology

More info on our PhotonWeld+ Real Portable LASER Welding Machines

Fiber Laser Welding with High Energy saving EcolEner® Technology

Unbeatable Next-generation welding technology

Weld till 75% faster

Rework till 90% less

Consume till 60% less energy

Lasermach PhotonWeld R Series - ROBOT-READY Fiber Laser Welding Packages

Robot ready fiber laser welding packages adaptable for ANY Robot

FASTER, More Precise, economical and safe Robot-Cobot laser welding with fiber laser

Replacing the previously convnetional MIG, TIG and MAG welding systems on every robot with a WOBBLE-R+ series fiber laser welding unit not only made welding much faster and economical but it also facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes laser welding by robot accessable to any company, which indicates that the majority of traditional welding of electric welding, argon arc welding, MIG, TIG, MAG, etc. will be replaced by laser welding.

PhotonWeld R-Series : Ready made fiber laser welding packages for robot and cobot

Air-cooled till 1600 Watt - Water cooled till 6000 Watt

With High Energy saving EcolEner® Technology

More info on our PhotonWeld R-Series LASER Welding Machines

Laser Cleaning Machines

Portable high precision Laser Cleaning Machines for all surfaces - High power laser cleaning machines for metal surfaces

LASER CLEANING

Laser Ablation Machine System

Using a Laser for cleaning is a process that removes debris, contaminants, dirt, or impurities (e.g. silicon cleaning, rubber cleaning, coating cleaning, carbon cleaning, etc) from material surfaces by using laser irradiation. With the development of science and technology, a new type of cleaning method appeared: laser cleaning, gradually replacing the traditional cleaning process. Laser cleaning uses a high-energy laser beam to irradiate the working surface, so that the dirt on the surface evaporates or peels off instantly, and effectively removes the surface adhesion or surface coating of the cleaning object at a high speed, so as to achieve the purpose of cleaning.

The benefits of using a laser cleaner are that it is extremely environmentally-friendly, has low maintenance and implementation costs, and has a widespread application use throughout almost any global industry.

Our laser cleaning technology provides a non-contact, cost-effective and environmentally friendly alternative to traditional techniques, which require the use of chemical or abrasive elements. Because they are fast, flexible, and robust, our laser cleaning systems can be effectively integrated into industrial machines to remove surface contaminants, such as rust, oxide or paint, and to pretreat the surface before subsequent manufacturing steps and texturing.Industrial cleaning is applicable in nearly every industry and can be applied to glass, ceramics, metals, concrete, plastics and much more. Laser cleaning is a non-contact, environmentally friendly process for removal of surface coating from metals, concrete and delicate substrates such as composites – with minimal impact on the base material. Lasermach portable system expands the cleaning from the floor to the field. Industrial Laser cleaning and surface removal can be applied to surfaces of bridges, aircraft, large vehicles, trains, cleaning tire remolds, laser mold cleaning, etc – in addition to small parts and sensitive materials.

Lasermach® offers an exceptional choice of premium fiber laser machines

Visit also our specific websites

Laser Welding machines: www.PhotonWeld.com

Laser Cleaning Machines: www.Photonclean.com

Laser Safety Equipment: www.photonsafe.eu

Laser Cladding Equipment :

www.photonclad.com (soon available)